Fighting fake medicines with Adfirmia™

A global pharmaceutical leader turned to EDGYN’s Adfirmia™ Digital Fingerprint to fight falsified medicines. The non-additive anti-counterfeiting technology integrates seamlessly into production lines, enables instant mobile product authentication anywhere, and delivers real-time intelligence to protect patients and strengthen brand trust.

Fighting falsified medicines with Adfirmia™ Digital Fingerprint technology

Customer background

The customer is one of the world’s leading pharmaceutical companies, recognized globally for its innovative medicines that improve and save lives across multiple areas. With operations spanning dozens of markets, the company has long prioritized the integrity of its products and the safety of its patients.

Challenges

The customer relied on an additive product authentication solution. This approach brought logistic complexity, higher operational costs, and limited scalability.

The goal was clear: move to an in-house, production-line-ready anti-counterfeiting technology that could provide secure product authentication, be easily deployed across diverse facilities, deliver real-time market intelligence to strengthen brand protection, and, most importantly, require no packaging modifications in order to avoid validations.

The new solution needed to address three critical areas:

- Technical requirements:

- Production line integration: capable of deploying directly on existing lines with different line configurations and speeds.

- Versatility in packaging: a single technology that works on all packaging types, including blisters, to avoid managing multiple solutions.

- In-field verification: instant authenticity checks using smartphones in any country, with potential for patient-facing programs.

- Centralized data visibility: real-time access to aggregated production, traceability, and verification data to enable faster detection of anomalies and proactive counterfeit prevention across different locations.

Solution

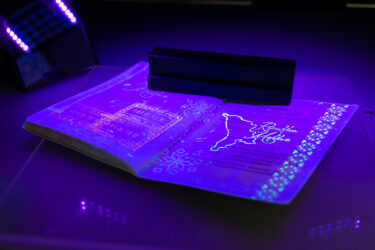

To achieve secure, scalable, and invisible authentication, the customer deployed EDGYN’s Adfirmia™ Digital Fingerprint technology across its global production lines. This smartphone-based technology captures a unique, impossible-to-copy digital signature (like a human fingerprint) from each product’s natural material variations, without adding anything to the product. As a result, Adfirmia™ delivers a non-additive, tamper-proof solution that cannot be copied, erased, or removed.

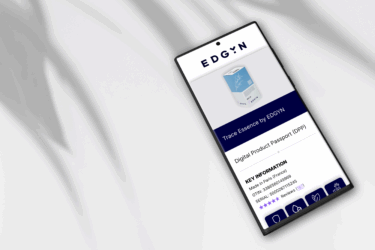

To support in-field verification, Adfirmia™ also enables mobile product authentication, allowing instant verification of authenticity directly via smartphone.

Results

The implementation of Adfirmia™ delivered measurable benefits across both production and field operations:

Factory level:

- Seamless integration: deployed on all types of lines — either as an autonomous unit or integrated directly — with no impact on production.

- Minimal disruption: solution installed during off-hours to avoid downtime in production lines.

- Centralized oversight: real-time visibility of site reports, production data, and line efficiency through a single web platform.

Authentication Performances:

- Wider verification reach: smartphone-based authentication significantly increased the number of product checks, therefore enhancing illicit medicine detection.

- Central data reporting and management: the web platform combined production, traceability, and verification data in a central database, allowing the Brand Protection team to monitor in real-time and adapt quickly when necessary.

- Patient engagement: infrastructure ready for patient reassurance programs, e-leaflets, and direct counterfeit detection.

Begin your brand protection journey

Protect your products from the inside out. Discover how Adfirmia™ can secure your supply chain, verify authenticity anywhere, and safeguard patient trust — starting today.

Discover more about Adfirmia™

Edgyn Shield

Edgyn Shield